Clean Rooms

Interlocking Floor Tiles

GTI Max Cleantech

- For cleanrooms

- High traffic environments

- Fast track innovovation

- Loose lay technical tiles

- Easy and quick renovation

- Watertight system

Product description

GTI Max Cleantech is a fast renovation flooring tile for cleanrooms and is a popular choice for Industrial and Medical and Pharmaceutical environments. These loose lay tiles offer a fast renovation solution which can be installed over most existing floors where minimal sub floor preparation is required, as well as no adhesives. The GTI Max range is cost effective both in the installation (you do not need to stop production or close the premises) and in terms of easier maintenance (with a PUR+ surface treatment). Best sellers are in stock now. * Please note we recommend using an anti-bounce mallet to install these tiles (Available to order: E6560002) - Please read full installation guidelines for further information or refer to our technical department.

Installation

- Adhesive-free

Slip resistance

- R10

Indentation

- ≤ 0.10 mm

Fire rating

- Bfl-s1

Fast Track - Renovation Flooring. Commercial Flooring - Cleanroom Flooring

Benefits of GTI Max Cleantech Flooring.

- Easy to clean and maintain floorcovering with PUR+ surface treatment reduces costs

- Available in 650 x 650 mm square format for hot welding where optimum hygiene is required

- Suitable for high traffic applications & withstands heavy rolling loads thanks to 2mm wear layer

- Also available in interlocking tile format (refer to GTI Max Connect for further information)

Product and Design:

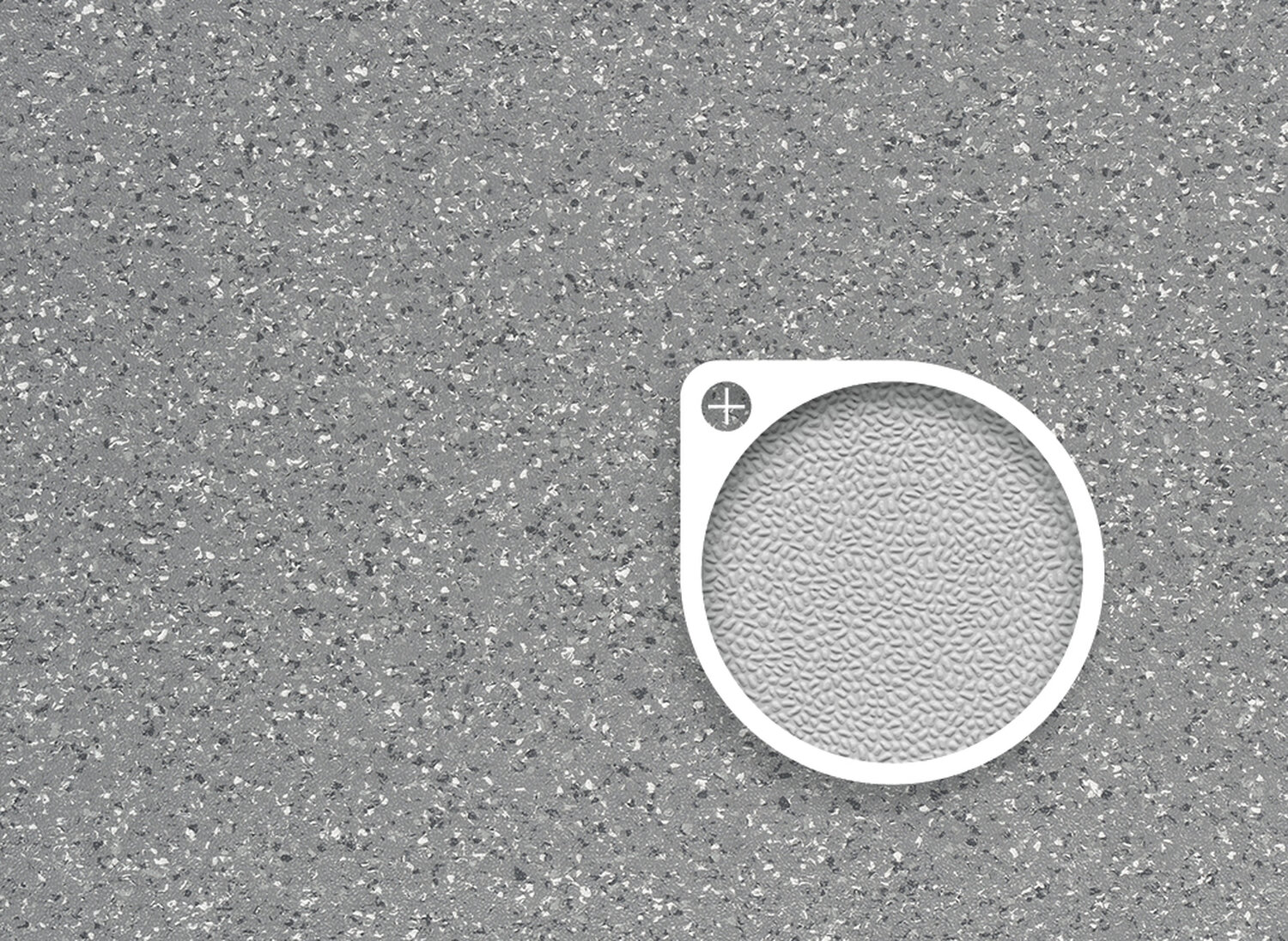

- PUR+ surface treatment for outstanding stain and scuff resistance & easy maintenance

- 2mm pure vinyl coloured wear layer for extreme heavy traffic resistance including fork lift trucks

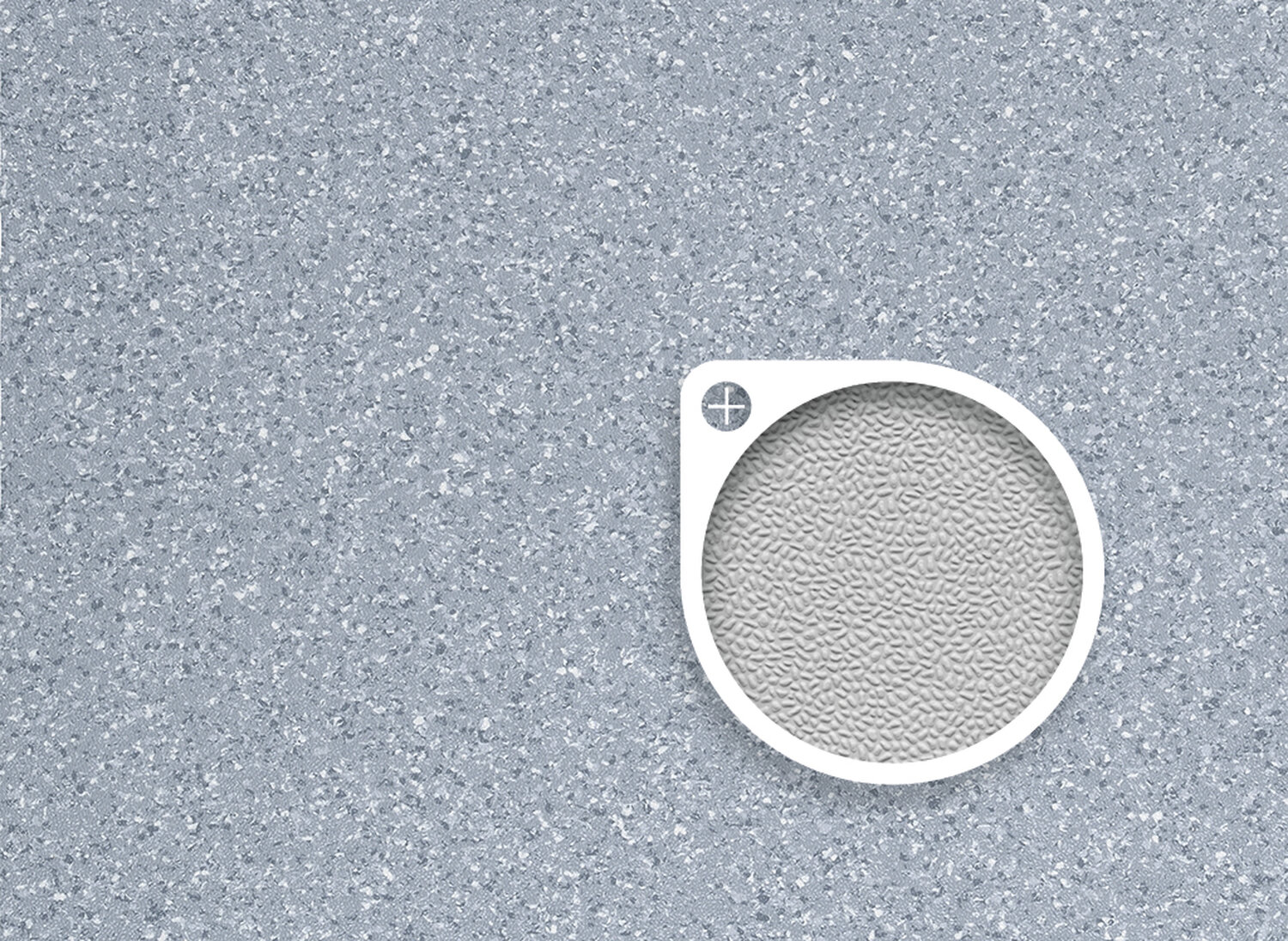

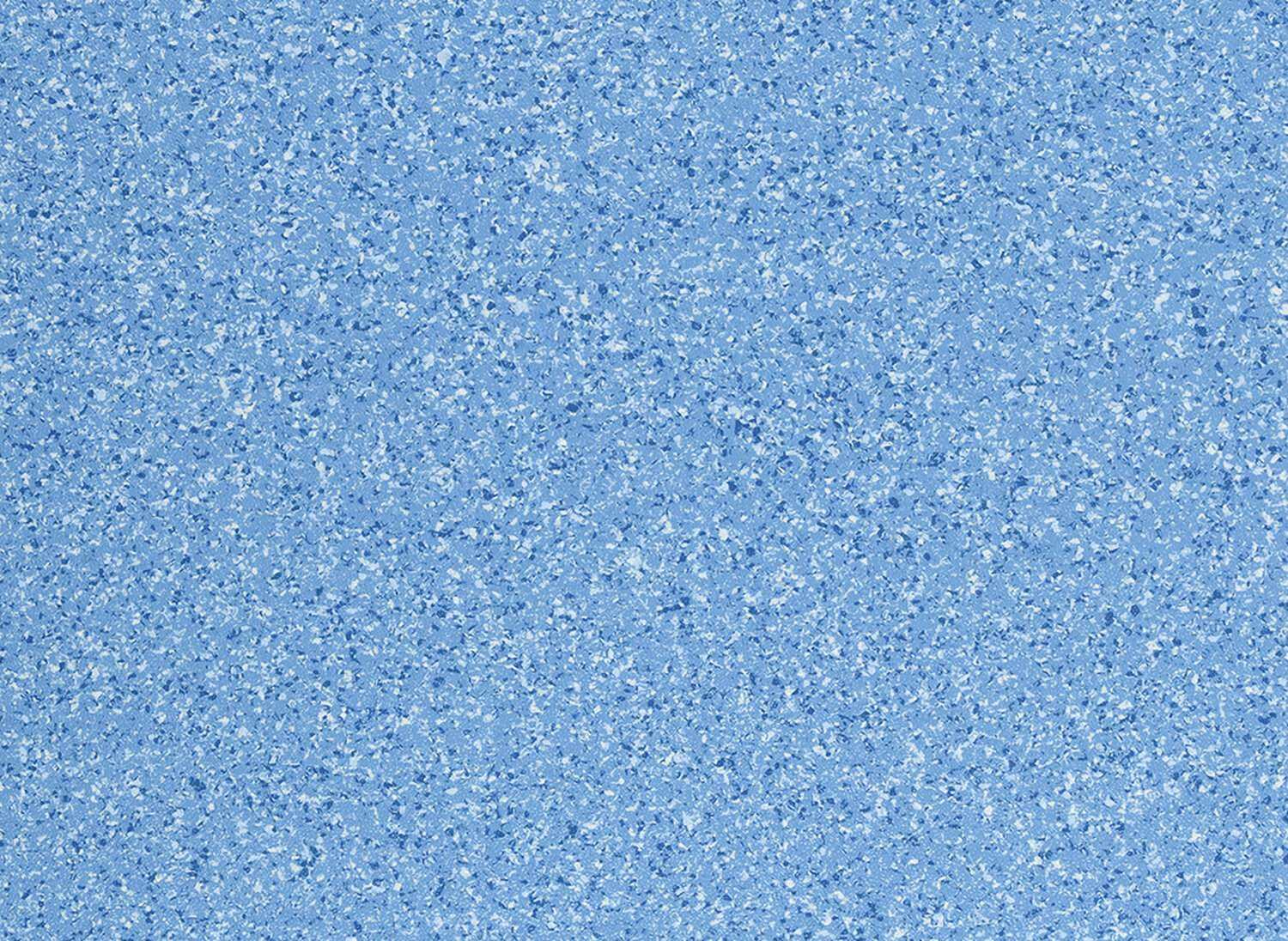

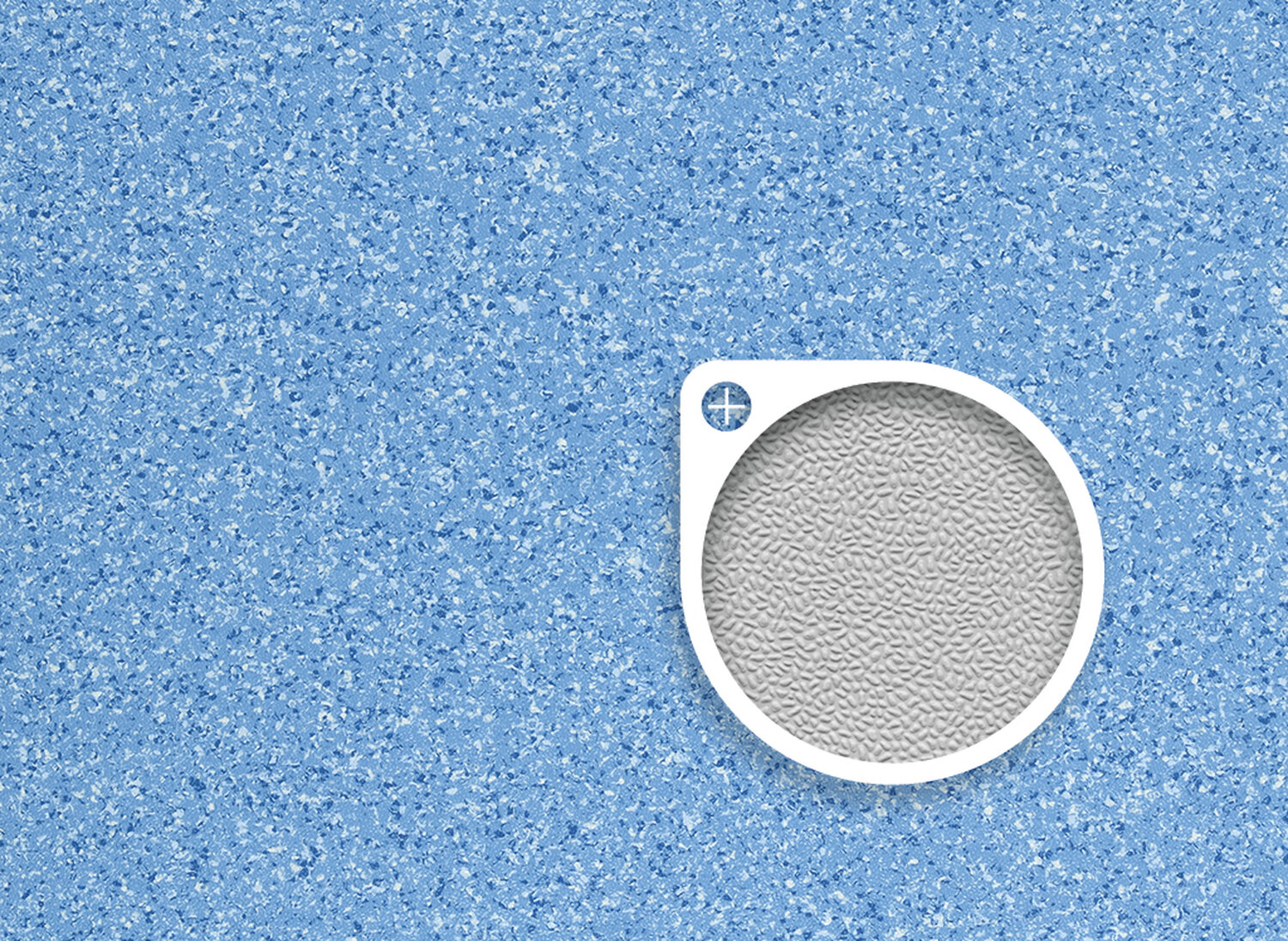

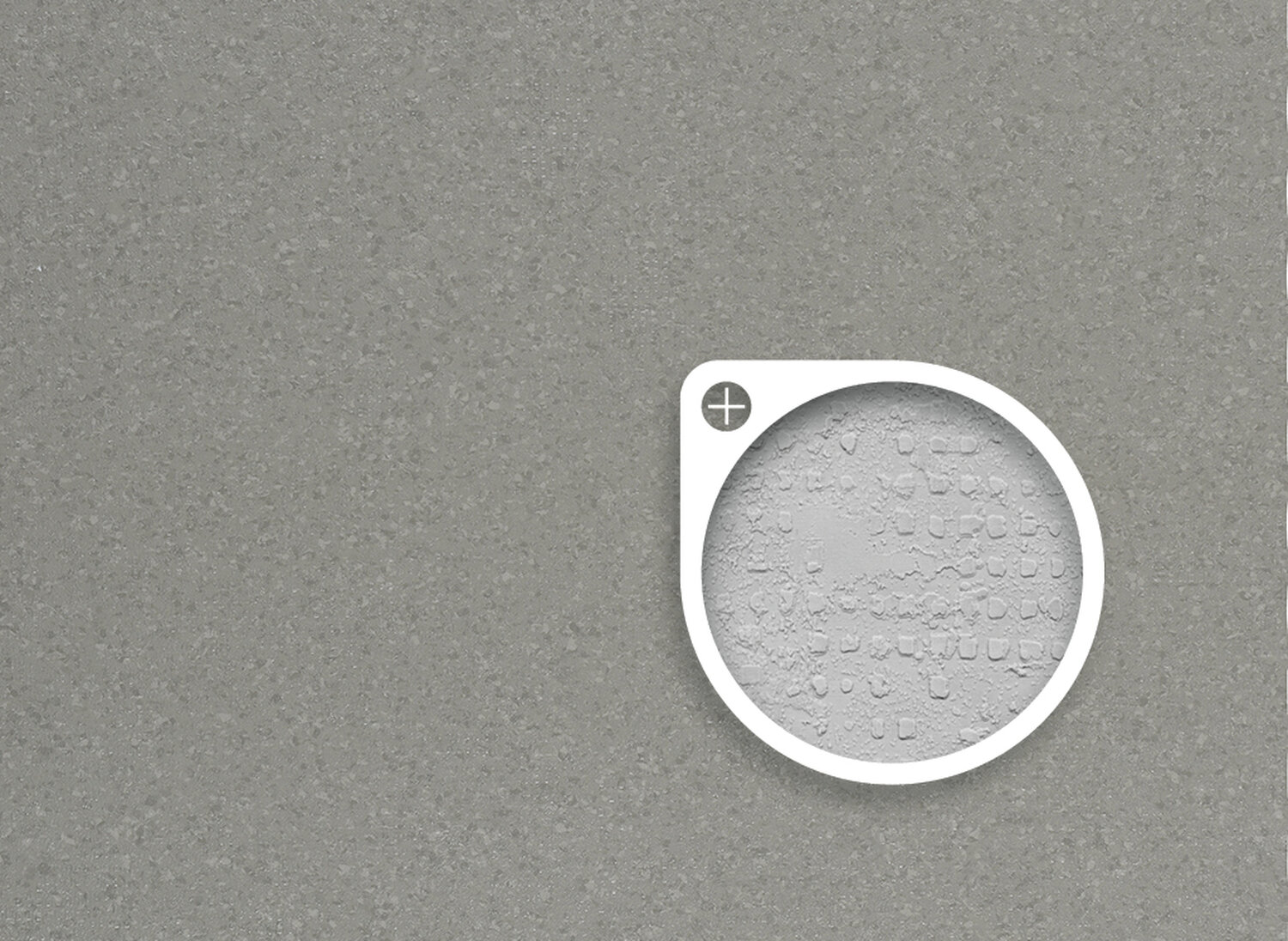

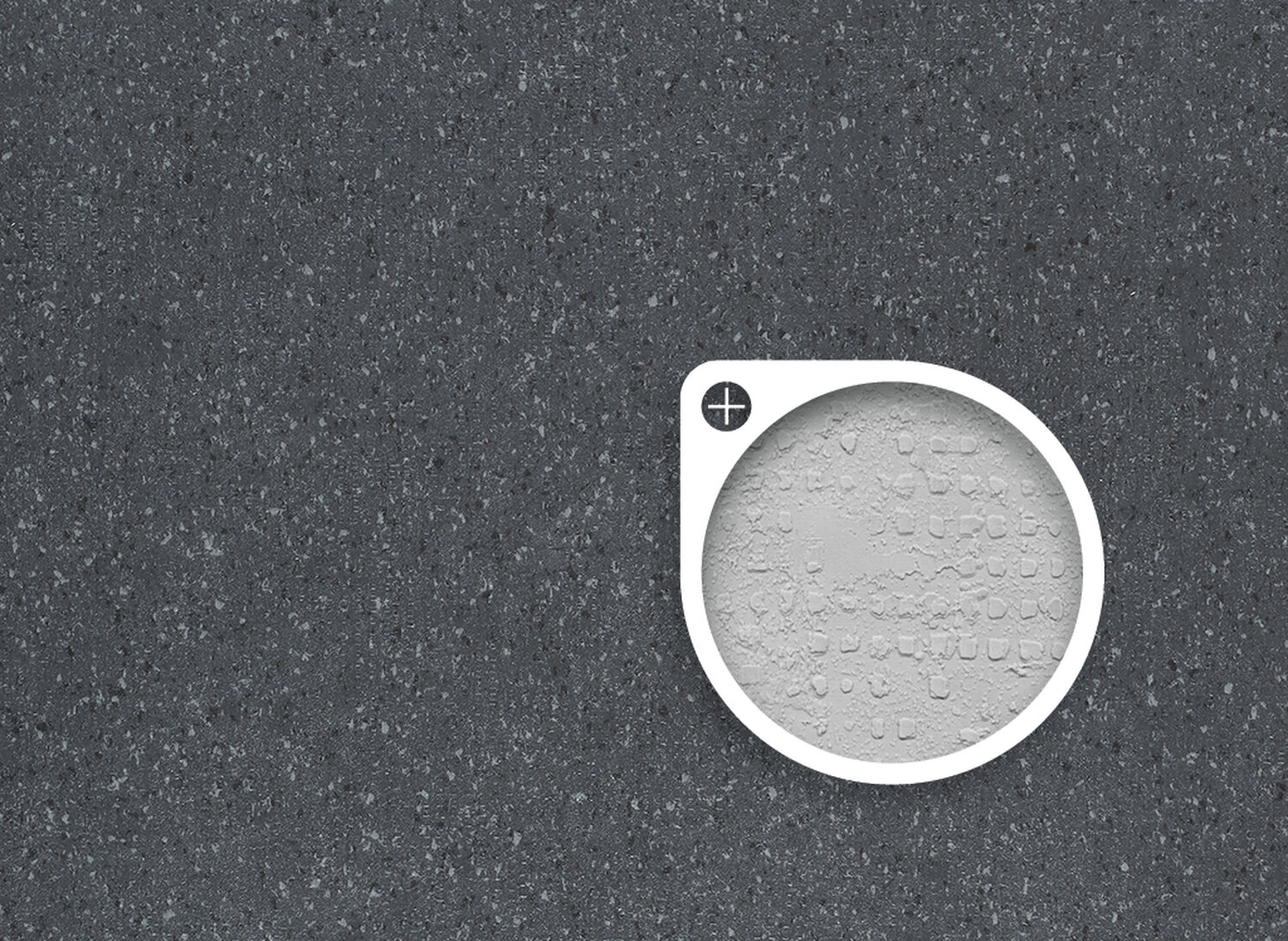

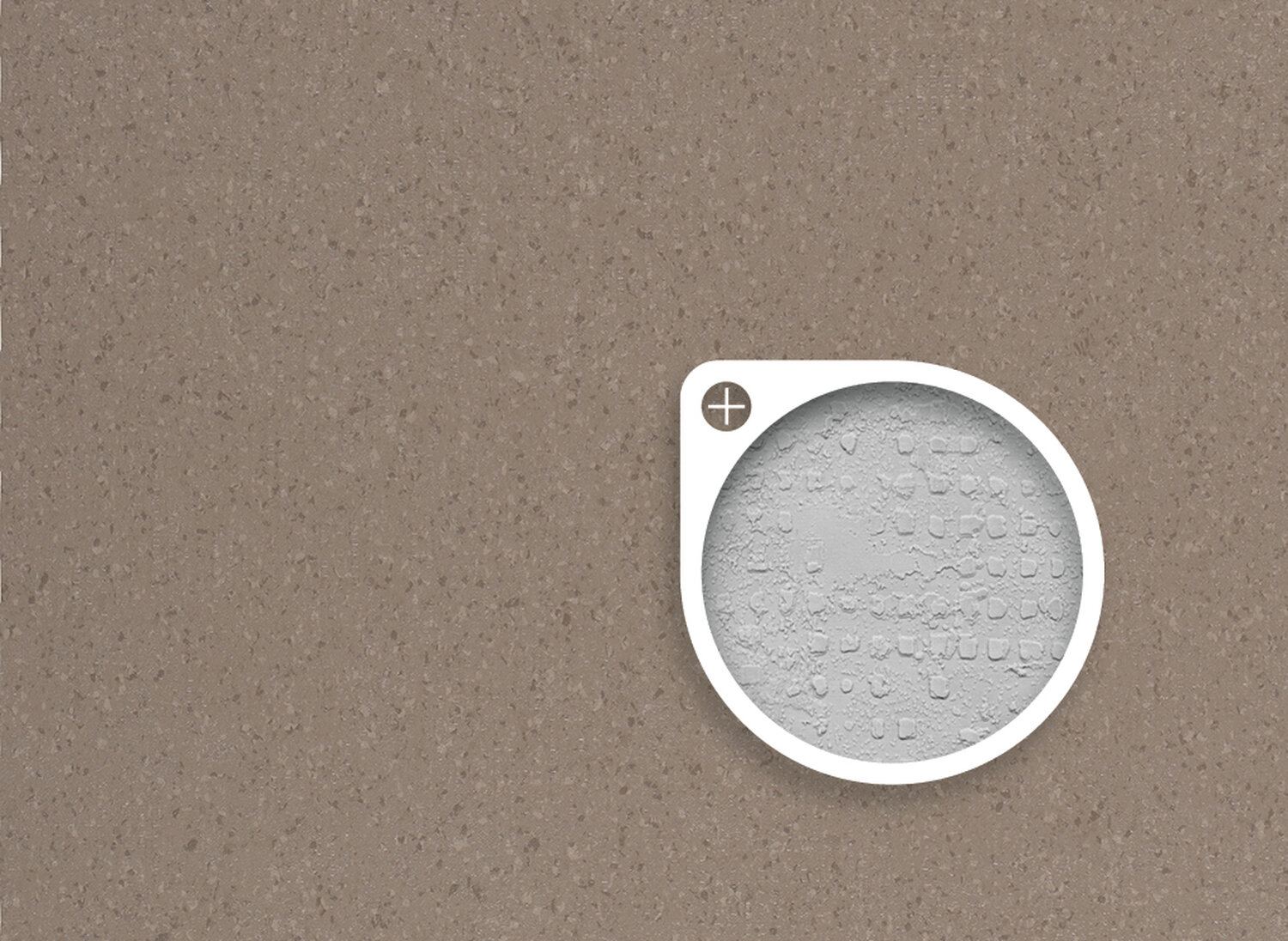

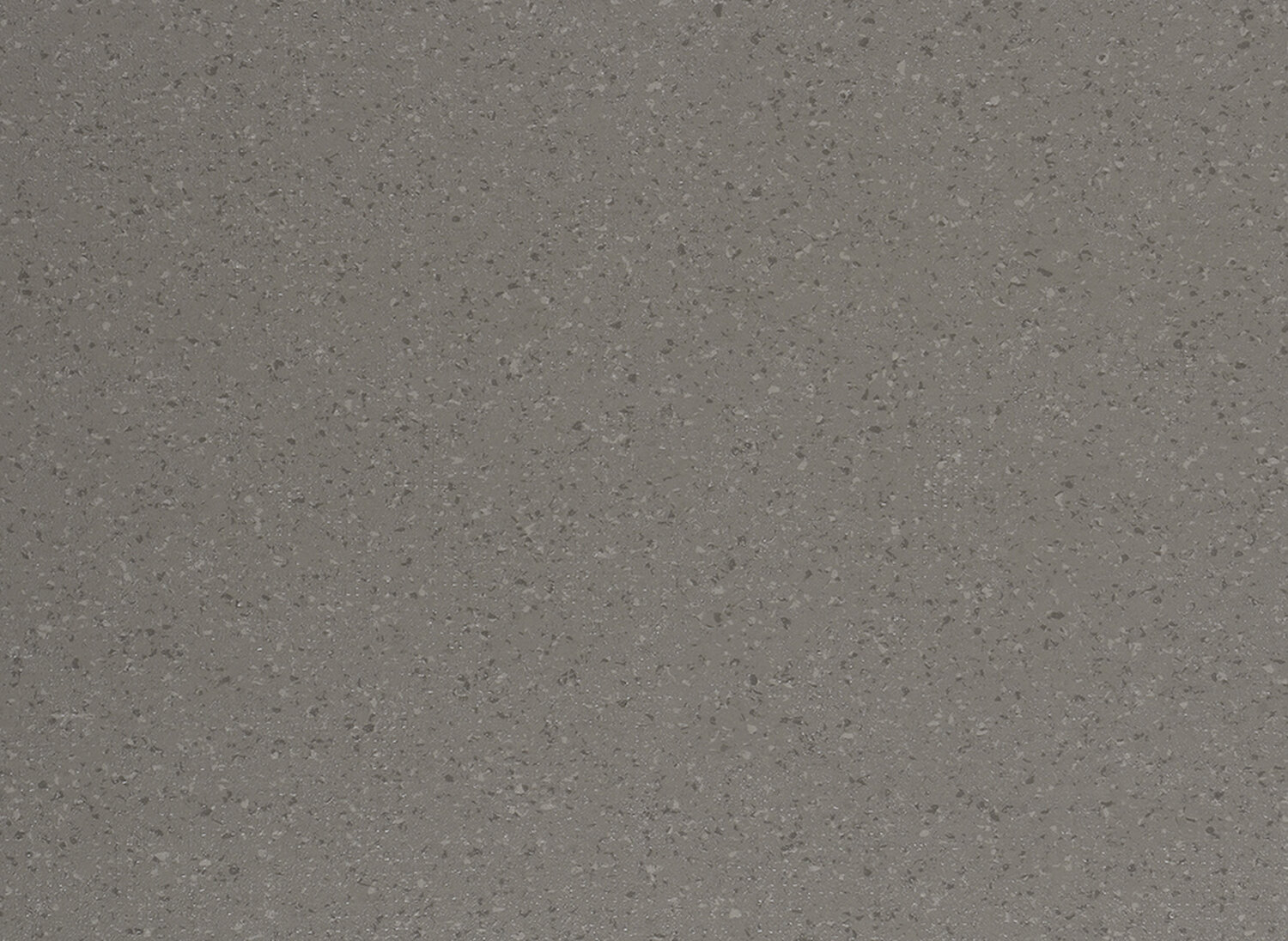

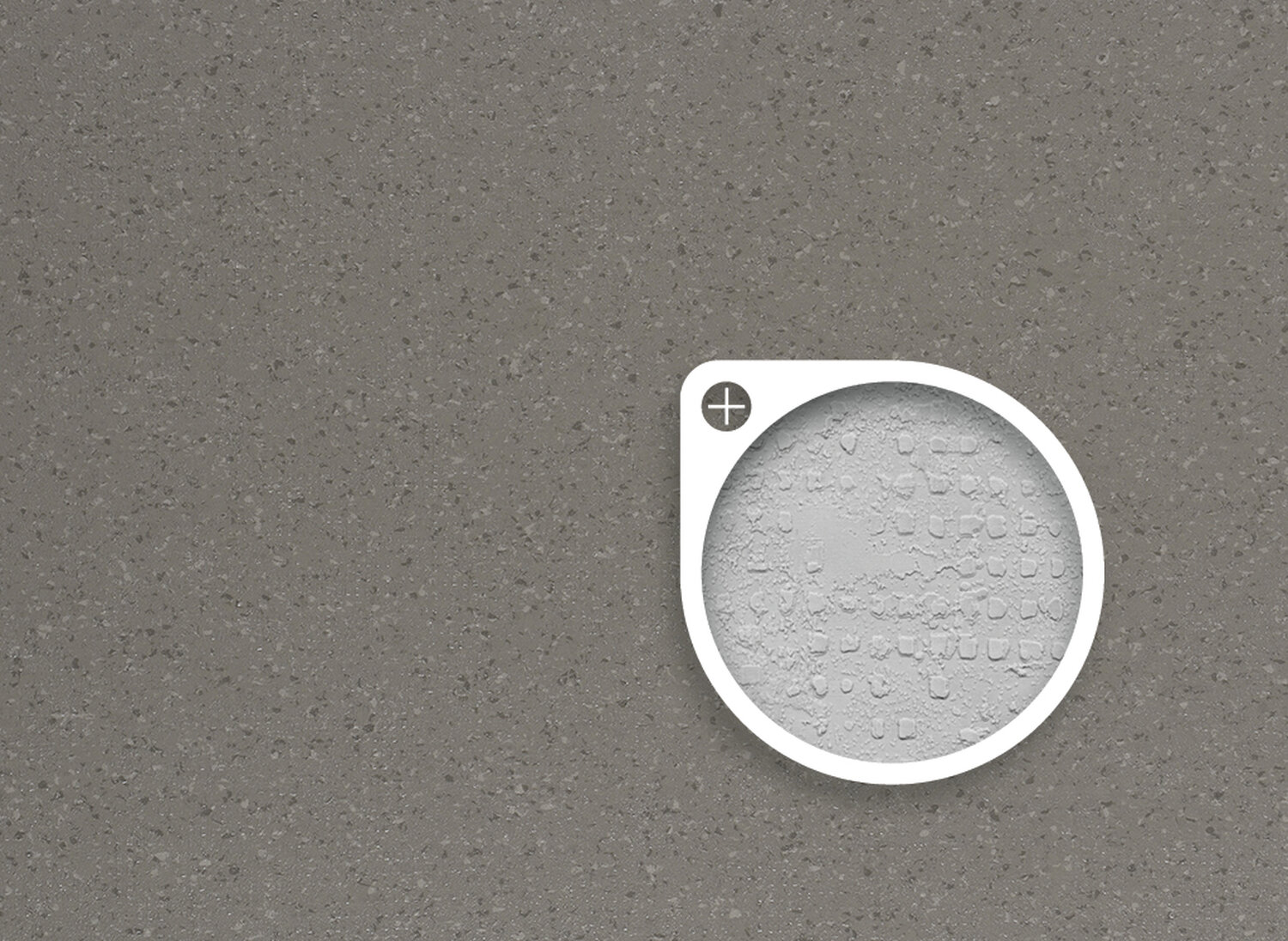

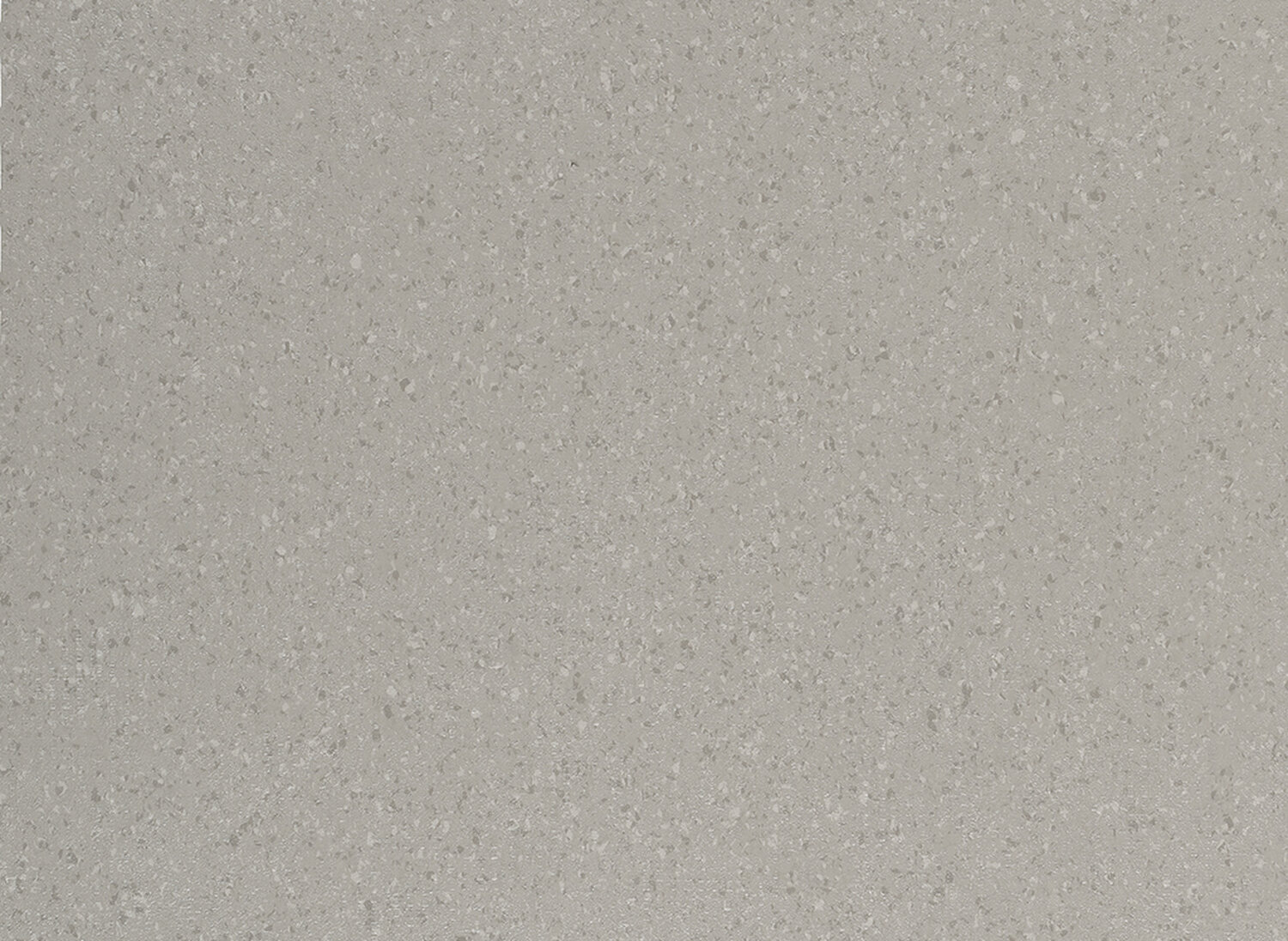

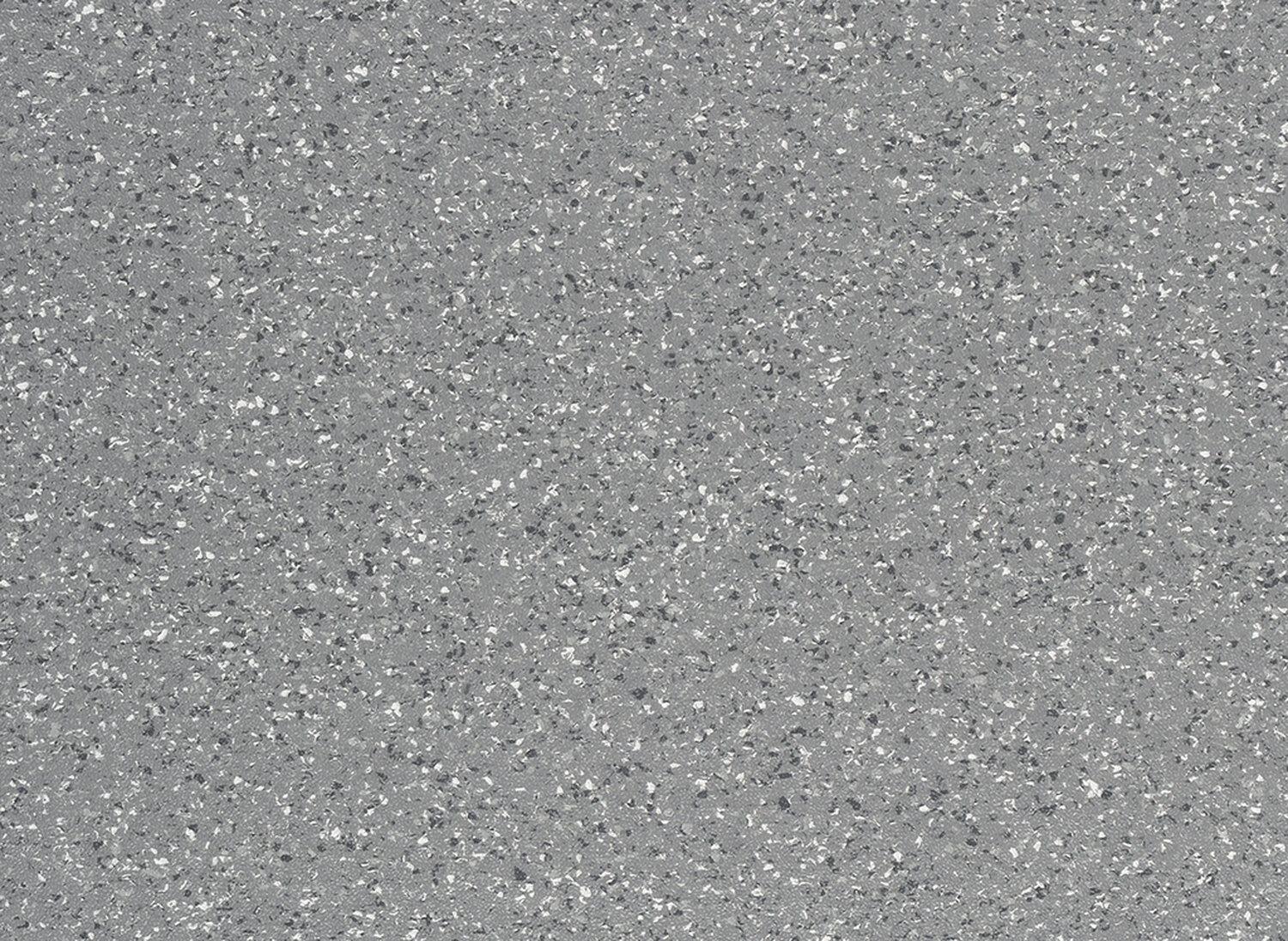

- 23 contemporary finishes in variety of popular colours for industrial & healthcare environments

Installation & Maintenance:

- Easy and quick to install, with reduced maintenance times and costs

- PUR+ surface treatment for unrivalled levels of stain and chemical resistance

- A versatile product that is easy to transport, cut and to install when time is of the essence

Market application:

- Ideal for all high traffic applications including Industry & Healthcare

- Applications include Cleanrooms and other locations where optimum hygiene required

Sustainability:

- Good indoor air quality => TVOC after 28 days < 100 micrograms/m3

- Health and safety => 100% REACH compliant, Phthalate & Formaldehyde (CH₂O) free

- Made in France => Reduced CO2 footprint of transport

- Preservation of resources => 100% recyclable

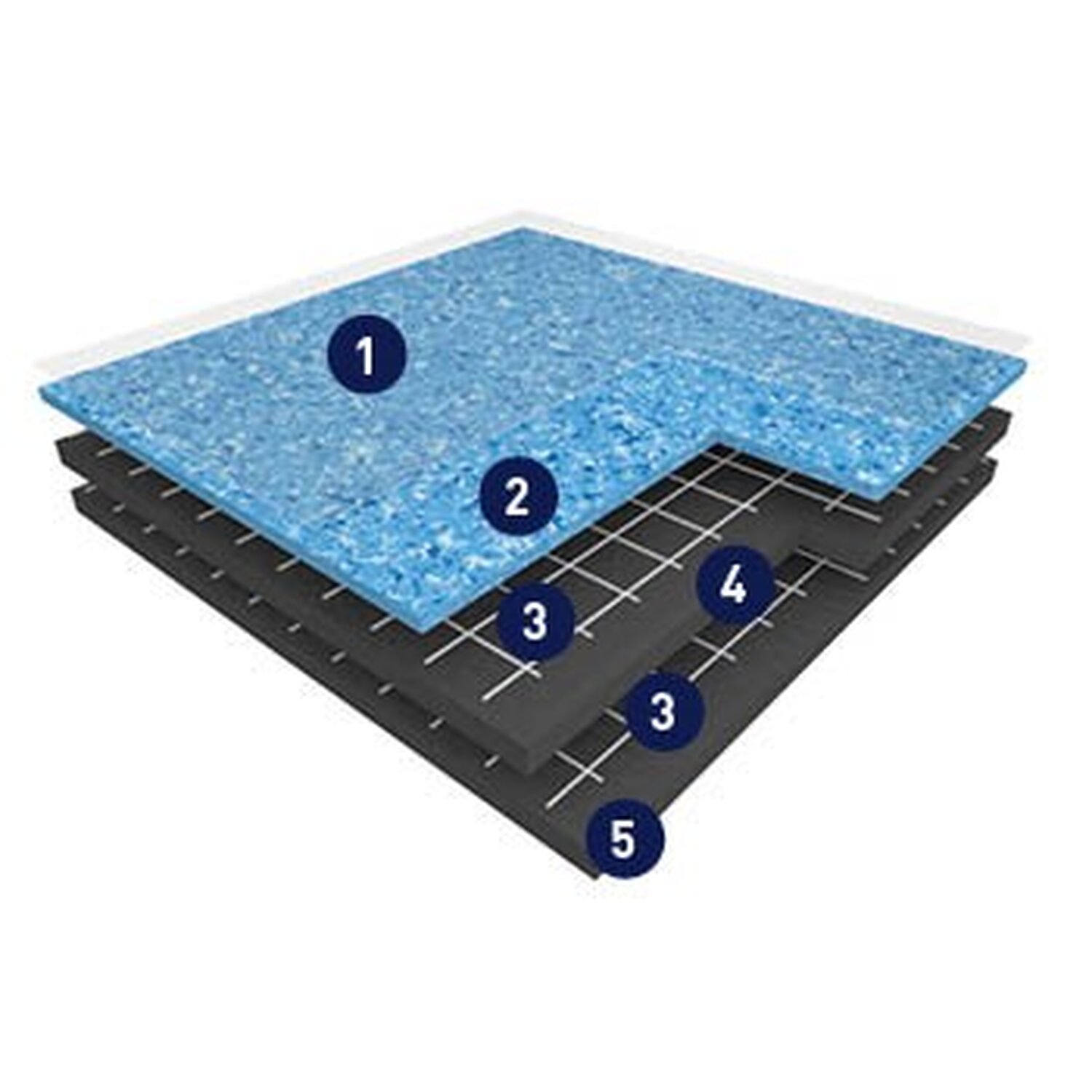

- Surface treatment

- Reinforced homogeneous PVC wear layer

- Glass fiber sheet

- 100% recycled compact interlayer

- 100% recycled compact base

Sustainability

Recycling rate

- 100%

Recycled content

- 80%

TVOC after 28 days

- < 10 µg/m3

Design

Interior Designer

Technical and environmental specifications

-

Characteristics

Value Surface treatment PUR+ Overall thickness 6.00 mm Thickness of the wearlayer 2.00 mm Installation system covering Adhesive-free Format details Square tile -

Performance

Value Reaction to fire Bfl-s1 Slip resistance wet shod feet R10 Wear resistance < 2.0 mm3 Electro conductive No -

Sustainability

Value Recycling rate 100% Recycling content 80% TVOC after 28 days with unit < 10 µg/m3

Documentation

Certificates

Commercial documents

Installation & maintenance